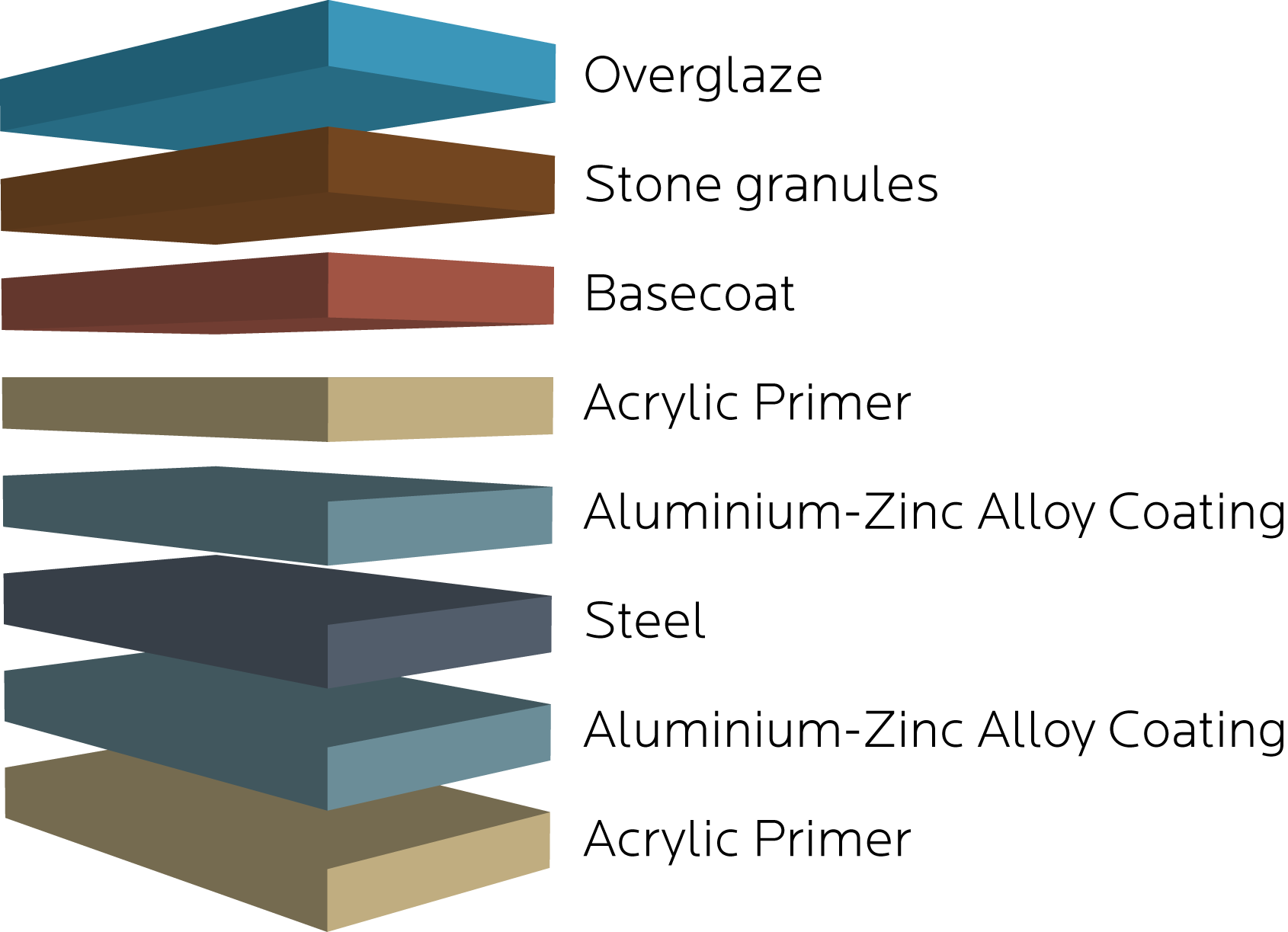

Steel Base

TACTILE panels are made from the high quality Korean steel. They are strong enough to withstand heavy loads loads while allowing profile designs with no damage to the structural grade steel base.

Aluminium-Zinc Alloy Coating

The steel base is protected by passing it through molten alloy of Zinc and Aluminium. It has the Aluminium-unique corrosion resistant and heat resistant qualities and the Zinc-unique “galvanic behaviour”. This corrosion protection of the alloy exceeds 50 years in majority of the conditions.

Acrylic Primer

An acrylic coating is applied to the treated steel panel immediately after the aluminium-zinc has been applied to the base steel. This enhances the strength and durability of the product.

Basecoat

A product called SMRC which is a type of adhesive that is used for the base coat during the process is applied to the base. It is an environment –friendly metal adhesion. It has excellent durability with abrasion resistant and weather resistant qualities.

Ceramic Coated Stone Granules

Naturally coloured basalt granules are then applied to the base coat. The different colours are obtained from different natural stones. These granules are ultra hard and have a high level of resistance to heat and mechanical stress.

Overglaze

An acrylic over glaze with UV resistant qualities is sprayed on as a final coating that gives the tile a finished look whilst simultaneously bonding together the stone chips.